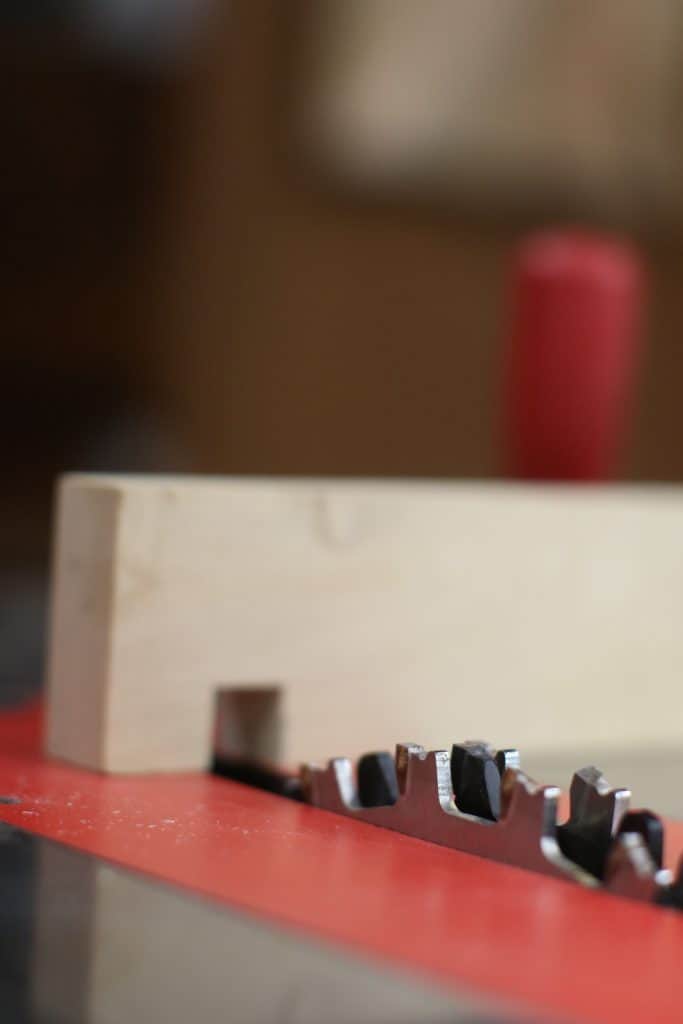

A table saw blade needs support at its center in order to connect with the rest of the saw’s components. A shaft, which is also referred to as a mandrel or spindle, extends from the motor to form what is referred to as the table saw’s arbor.

So an arbor is a motor shaft that holds the blade. Yet, why do table saw arbors have flat sides?

Contents

Why Do Table Saw Arbors Have Flat Sides?

A table saw arbor has flat slides because they hold the blade in place. If the sides of the arbor are not flat or have bumps, this can cause the blade to wobble.

The motor of the saw turns the arbor, in turn causing the blade to rotate safely. Given that the blade needs to move at a very high speed in order for a table saw to function effectively, the arbor should have flat sides to facilitate the blade’s seamless rotation.

An arbor holds the blade of a table saw firmly in place and also determines the tilt of the blade. The arbor has a machine-made flange on its right side to prevent the blade from sliding far away.

It also has a threaded shaft which has a large cup-shaped washer and a nut to grip the blade.

The sides of the arbor should be totally flat so that there is no gap or bump that can cause the blade to wobble. The level of flatness of the arbor also determines the run-out level of the arbor, which is the amount of wobble that you can see as the blade rotates.

Table Saw Arbors and Blade Wobbling

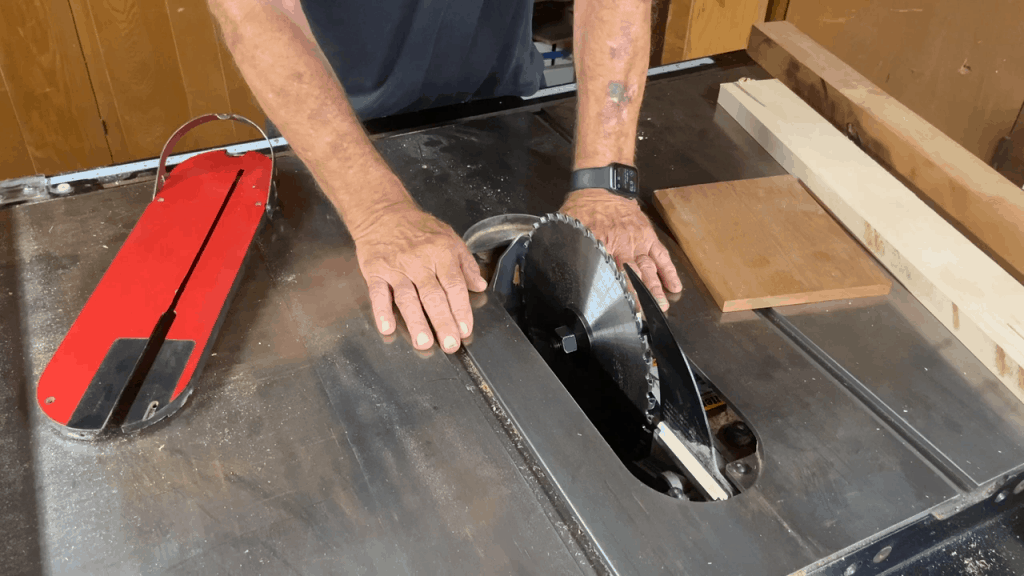

If the arbor of your table saw is not as flat as it should be, is loosely fixed, or has some dirt, this can cause the blade to wobble.

- Bumpy or dirty arbor: If the arbor has bumps due to dirt or any kind of damage, this can cause the blade of the saw to wobble. Bumps imply that the surface of the arbor is not as flat as it should be, and the contact that the bumps make with the blade causes it to wobble as it rotates.

- Arbor with loose nuts: Loose nuts are a sign that the blade is not tightly attached to the arbor. The resulting gap between the arbor and the blade will cause the blade to wobble as it moves at a high speed.

‘Allowable’ Blade Wobbling (Run-Out)

You need to regularly check the blade of your table saw to ensure that it does not wobble beyond the permissible levels. Any kind of wobbling of the blade means that the blade is not positioned fully parallel to the arbor. This, as noted above, may be due to a bump, dirt or a loose nut.

You can check the amount of wobble or run-out of your blade using a dial micrometer. If the run-out is too large to be tolerated, you will be able to see the blade’s wobbling as the blade slows down when the saw is turned off.

Importance of an Arbor’s Flat Sides in Relation to Cutting

The quality of the cuts that you make using your table saw depends on how well the blade is positioned in the arbor. The positioning is in turn determined by the quality of the arbor. The more the blade is able to rotate without wobbling, the more you will be able to make straight cuts.

An arbor’s quality depends primarily on the level of run-out that the arbor has. A run-out below .003″ is regarded to be acceptable by many experts while a value above .010″ is regarded too bad and hence unacceptable.

Well-threaded arbors are machined to accurate tolerance to provide a more exact fitting of the blade. The threading of the shafts is usually done in a direction that is opposite to that of the blade’s rotation. This arrangement enables the blade to get tighter as it turns.

If for some reason the sides of your table saw’s arbor are not flat, you may experience an unacceptable wobble.

How Tight Should a Blade Be Attached to the Table Saw Arbor?

The arbor nut should be more than hand tightened, but not overly tight. You should tighten the nut to such a level that you can use your wrench to loosen it while holding the blade with your hand safely.

It should not be easy to get the nut loose by hand. At the same time, over-tightening can cause damage to the arbor.

Conclusion

Table saws have flat sides because the sides help hold the blade in place. The sides of the blade should not have bumps since bumps can cause the blade to wobble. The arbor should also have an acceptable run-out and be well attached to the blade to allow the blade to cut straight.

![Best Circular Saw Blades in 2023 – [Review & Buying Guide] 8 Best Circular Saw Blades in 2023 – [Review & Buying Guide] Best-Circular-Saw-Blades](https://brandisawyer.com/wp-content/uploads/2020/06/Best-Circular-Saw-Blades.jpg)